The 5 Steps – Part 7 of 11

In the last OneThingology Blog post, we talked about Finding Waldo, finding or identifying the constraint being the first of a five step process, so today we will take a step back and reveal The 5 Steps.

I would suggest that these 5 steps are the steps to illumination. Each step you take builds upon the last, helping you to separate the wheat from the chafe, the important from the insignificant, the symptoms from the core issues and/or problems.

The first question that begs an answer is what are these 5 steps? Not to belabor providing you with the 5 steps, but TOC (Theory of Constraints) actually has a step ZERO, so let’s spend a couple minutes on Step ZERO.

Step 0: What is the GOAL?

If you have not read the book ‘The Goal’ by Eli Goldratt, you really need to do that as soon as humanly possible. It’s a love story about manufacturing, making it really easy to read. In this book, Jonah uses the Socratic Teaching Method (teaching by asking questions, or sometimes referred to as argumentative dialog) to teach Alex Rogo how to manage his manufacturing business.

Before Jonah would help Alex, he insisted on knowing what the Goal of the business was, what they were trying to achieve. A good portion of the beginning of the story is devoted to this one thing, and understanding this “One Thing” is a prerequisite to success. Ultimately, the summed up Goal was determined to be Making More Money Now And In The Future. We will talk more about this Goal in future articles, but suffice it to say that the wording is precise and intentional as it relates to the business, AND that we also need to clearly understand the last point Jonah makes in the book, that our business Goal is NOT our personal Goal.

Let’s focus on this for just one moment. The first thing that Jonah covers, and says is of preeminent importance is also the last thing he covers, but making the distinction between our Business Goal and our Personal Goal, making sure we understand that they are two very different things. Far too many business owners sacrifice their personal life on the alter of their business life, ultimately failure in either will affect the other, and not in a good way.

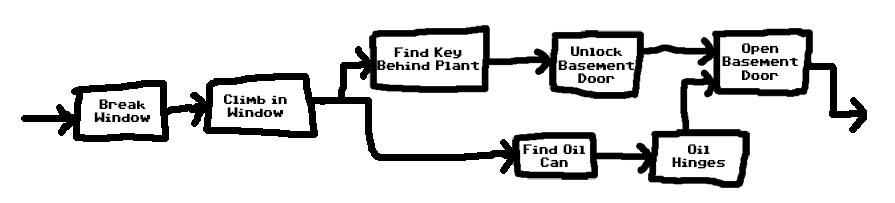

All manufacturing businesses are made up of a series of DEPENDENT events (you have to machine the cabinet parts before you can assemble the cabinets, you have to deliver the cabinets before you can install the cabinets), and this dependency is what far too many managers/humans ignore. The same can be said about our personal and business lives, each is dependent on the other, but they are and should be separate. In reality we are 3 dimensional beings; mental, physical and spiritual, and each dimension is dependent on the other two. We can and do get away with ignoring dependency for a time, but ultimately, ignoring one will ALWAYS affect the other two. Maybe not today, or even tomorrow, but given enough time and challenges, failure will come on the heels of ignoring dependency. We need to feed our minds, bodies and spirits daily.

So, what is the Goal of your Manufacturing System? Write it down, frame it, hang it on the wall, post it throughout your company. Everyone that works for you should be able to quote it verbatim anytime you ask. Make it the litmus test for everything your company does (we don’t do things that don’t help us reach/make our Goal). BUT, know that making more money now and in the future is NOT your personal Goal (if it is, then we need to talk, preferably with your entire family in the room).

So now that we have Step ZERO out of the way, let’s identify the Five Steps, or maybe the better way to say that is just like Eli Goldratt liked to say it, the Five Focusing Steps.

- Identify the Constraint

- Exploit the Constraint

- Subordinate every other decision to the Constraint

- Elevate the Constraint

- Rinse and Repeat

These Five Focusing Steps are in my opinion what separates TOC (Theory of Constraints) from Lean. Anyone that knows me knows I am a fan of Lean, but anyone that knows me well knows that I think Lean should always be subordinated to TOC. TOC helps us focus on what we need to do/change, Lean provides the tools to make the changes. In the absence of TOC, Lean can actually hurt our businesses if we are not very careful in the implementation. Fixing what bugs you sounds good and right, but fixing symptoms of core problems can be expensive, and in companies that have limited resources (I have only known a few businesses that don’t have limited resources, or that their resources far exceed their needs, Google, Apple and Amazon are just a few of these exceptions to the rules of limited resources), we can kill cash flow by investing those limited resources to fix symptoms of core issues, leaving the core issue in place, and gaining nothing more than phantom improvements (improvements in name only, improvements that do not enable or empower more throughput).

Trying to fix everything at once can be dangerous when we consider limited resources (limited time and money), and if the fix does not address the weakest link, it will only provide a phantom improvement, an improvement that will only enable or empower your people to pile more parts (Work in Process or WIP) in front of the constraint or weakest link (a chain is only as strong as its weakest link). You won’t produce more FINISHED product, just more WIP, exacerbating the Constraint. And if you don’t produce more FINISHED product, you won’t bill for more finished product, thus you won’t collect checks/money for more finished product. The Goal of a company is NOT to make more WIP now and in the future.

On the other hand, if we focus our resources on the Constraint, enabling or empowering the weakest link to make more billable stuff, a whole bunch of those SYMPTOMS will go away as a result, and we won’t need to spend a dime to improve them (they were simply symptoms of the constraint). In my opinion, and I consider it a well informed opinion, not investing our limited resources on improving symptoms of core issues is the ultimate elimination of Waste. Feel free to quote me on that, feel free to tweet that.

So let me sum up. DO NOT IGNORE DEPENDENCY. NEVER, EVER IGNORE DEPENDENCY, PAY ATTENTION TO DEPENDENCY. In any system of dependent events, there will always be a weakest link, a constraint, that “One Thing” that limits the system from achieving it’s Goal. The Five Focusing Steps help us Focus on that, empowering us to Make More Money Now And In The Future.

In the previous two articles in this series, we covered the first step fairly well (Where’s Waldo and I Found Waldo). In our next article in this OneThingology series, we will delve into the second step, Exploiting the Constraint.

To make sure you won’t miss a crucial part of this discussion, enter your email address in the Subscribe to Blog via Email field on the right, and each time one of us adds a blog post, you will automatically be notified. Oh, and you won’t hurt our feelings if, depending on where you are seeing this, you Share, Like, Plus or Re-tweet it (there are buttons somewhere on this page to help you with that).

May the Lord bless the work of your hands, heart and mind.